-

Adaptive Thermal Systems (ATS™)

(1).png)

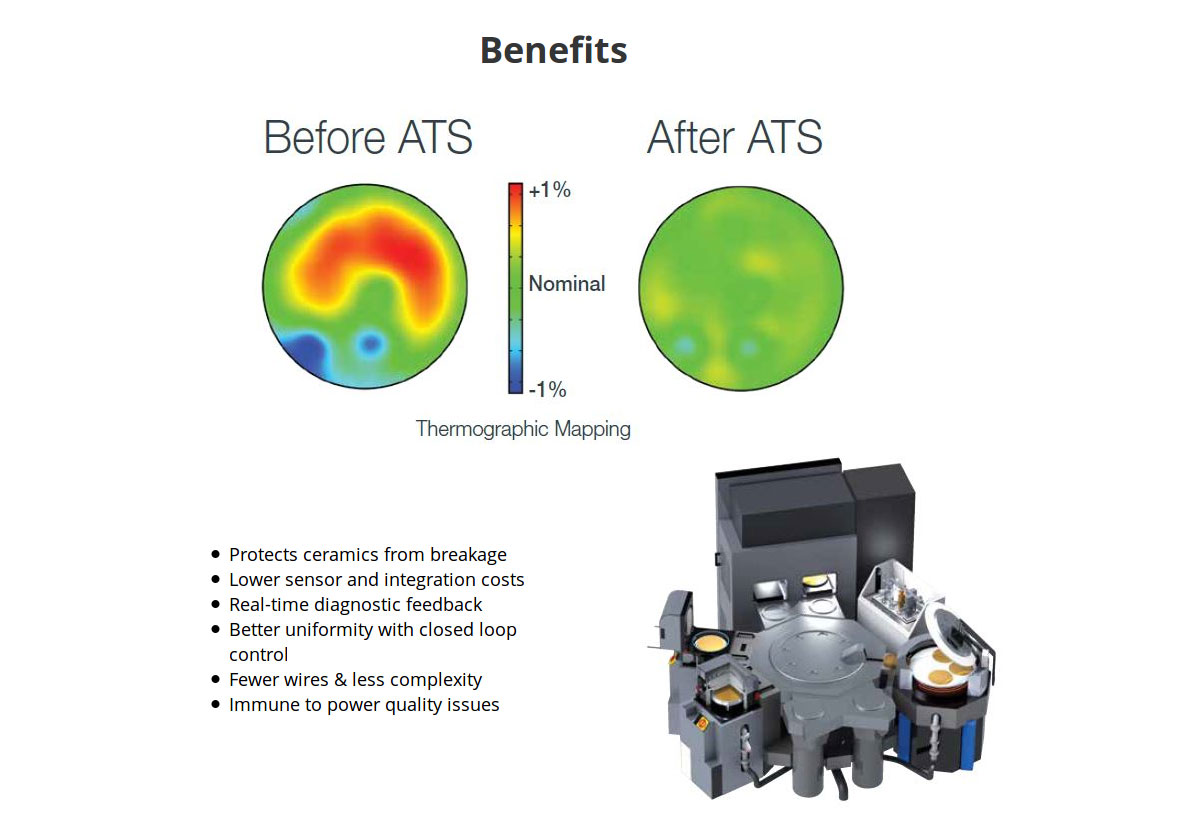

Watlow’s Adaptive Thermal Systems (ATS™) are a suite of technologies that combine sensing, heating and controlling in innovative ways to improve the thermal performance of a customer’s application. ATS technology integrates foundational technology platforms including power conversion, multi-loop control and sensing, integrated TCH junction temperature control and high TCR materials based temperature control to optimize performance that is specific to the problem being solved.

Historically, engineers have compensated for system variation with inadequate information. With ATS technology users now have the ability to listen and respond to the materials to enhance and simplify performance. ATS enables engineers to close the open loop and see what is going on in the system in real time. For example, locations where temperature sensing was previously impractical can now be measured utilizing heater circuits as additional sensors. Also, increasingly complex wire routings are simplified by using innovative multiplexing methods to integrate additional zones of control. Furthermore, heaters that have been design constrained due to geometry or electrical resistance can now be driven with an appropriately scaled down voltage level.

.jpg)

High TCR Material Based Temperature Control

Measure change in resistance to convert every heater to sensor

.png)

.jpg)

.png)

-

HTUK staff take part in the Great North Run for Charity

The Great North Run takes you from Newcastle city centre, over the iconic Tyne Bridge and to the finish near the coast in South Shields. You’ll be one of 57,000 people taking part and you’ll see as many of those aiming for PBs as you’ll see in fancy dress. Plus, remember to look up to see the infamous Red Arrows!

Something that struck very close to home recently was the fact that Breast cancer is the most common cancer in the UK.

Breast cancer starts when cells in the breast begin to divide and grow in an abnormal way. It’s caused by a combination of lots of different factors, many of which are beyond our control.

Breast cancer is not one single disease – there are several types of breast cancer. It can be diagnosed at different stages and can grow at different rates. This means that people can have different treatments, depending on what will work best for them.

We are proude of the HTUK team that entered for this great event and raise over £1000 - Thank you to all who donated to this cause.

Conragtulations to Mark,Chloe, Richard and Michael enjoying the refreshments!

-

Watlow Training Conference

HTUK participated in the recent European Watlow training conference held near the Watlow Plasmatech plant in Austria. Extensive training on the new F4T process controller was provided by personnel from our Winona Plant. USA

Great couple of days to meet up with the rest of the European team.