0191 5166636

enquiries@ht-uk.com

APPLICATIONS:

- Wafer Cleaning & Rinsing (Wet Bench Systems)

- Heating of Flow-Flashpoint Solvents & Acids

- For Use with Single Pass or Recirculating Systems

- Similar Uses as PFA-Tube Heaters, but Higher Temp Limits

- Processes Involving Explosive Vapors

- Situations where Exact Temperature Control is Critical

FEATURES & BENEFITS:

- Fluid Path has No Contact with Heating Elements

- Allows for Safe Heating of Low Flashpoint Solvents

- Heated Media is Isolated in Seamless 316 Stainless Steel Tubes

- Solvent Tubes are Passivated and Electro-Polished for Purity

- Self-Draining Flow-Tubes Eliminate Trapped Debris

- Cooling Tube Quick Reduces Heat Below Flashpoint

- NEMA 7 Explosion-Proof Electrical Enclosure

- Equipped with Robust Sensor & Switch Array

Specifications:

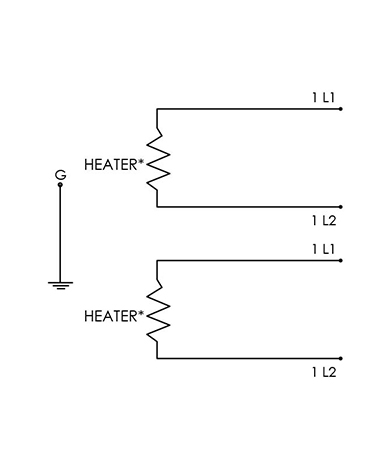

Power:

- 6 kW Total to 8 kW Total

- Voltage Range: 208 - 480 V

- Max Line Current: 30 A per circuit

Tubing (Solvent Tube):

- .750” OD (3/4") (19.1 mm)

- .065” Wall (1.7 mm)

- Overall Process Tube Length: 115.5” (2934 mm)

- 316L Stainless Steel, Passivated & Electro-Polished

Tubing (Cooling Tube):

- .250” OD (1/4") (6.3 mm)

- .035” Wall (0.9 mm)

- Overall Process Tube Length: 86.25” (2190 mm)

- 316L Stainless Steel

- Max Pressure: 3100 psi (213 bar)

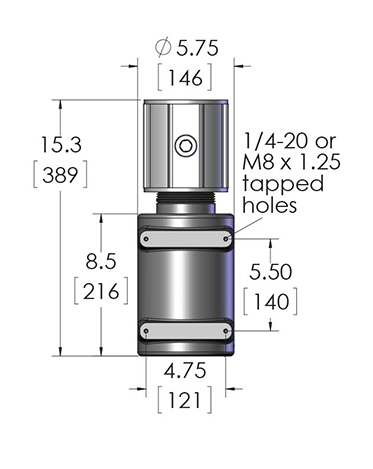

Enclosure:

- NEMA 7 (explosion-proof)

- (Class 1, Div. 1 and 2, Groups B, C and D)

Max Working Temperature:

- 392°F (200°C)

- Published temperatures are for housing at 12 o’clock position;

- Higher temps may be possible at 6 o’clock position. See factory for details.

Sensors:

- Two J-Type Thermocouples (cast in)

- One J-Type Thermocouple (removable)

- Snap Action High Limit Switch (with auto reset)

Fittings:

- Solvent Tube: Flaretek®-Compatible or Swagelok® VCR

- Cooling Tube: NPT or Swagelok® VCR

Available Accessories:

- Insulating Jackets

- Compression Fittings